in-Tec Bensheim - since 1996 partner for

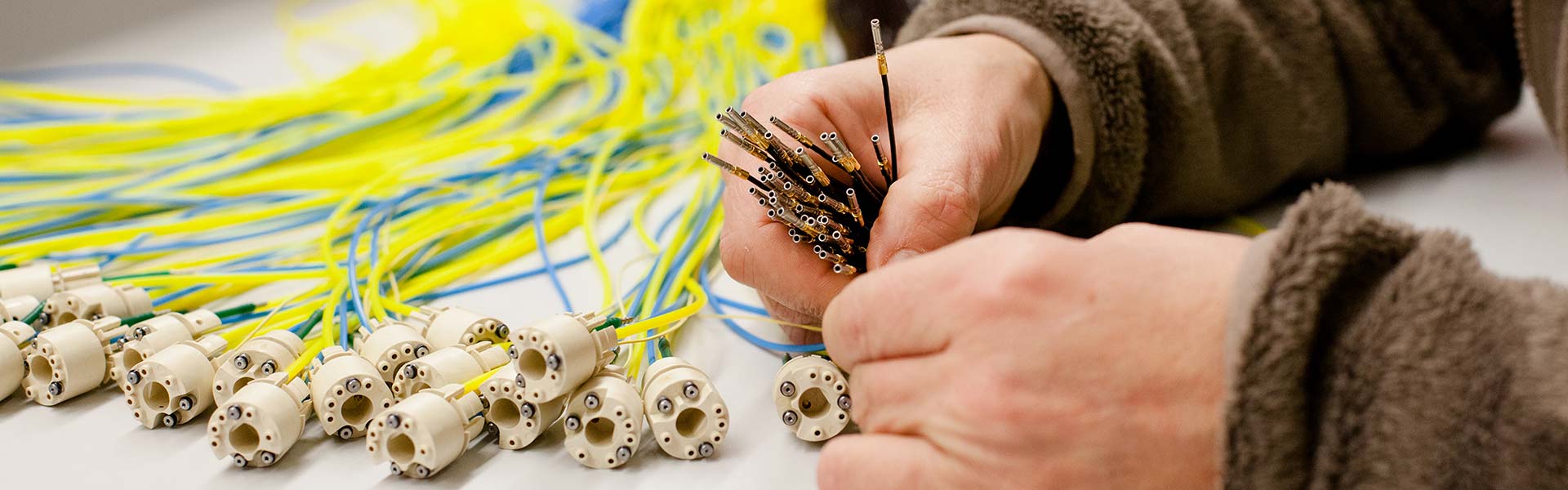

module assembly and cable assembly

Our services cover various subject areas. We have made a list of selected topics. Find out more about it by clicking the keywords below: OEM manufacturer, Assembly of components, Component assembly, Assembly production, Device assembly, Cable assembly, Component assembly mechanical engineering, Micrograph analysis, Crimping machine, Assembled cables, Cable crimping, Cable assembly Germany, Confectioned cables, Individual cable assembly, Cable assembly online, Cable assembly electrical engineering, Cable harness production, Cable harness manufacturer automotive, Electrical assemblies, Contract assembly