Topic areas

Contract assembly

OEM manufacturer

Assembly of components

Component assemblyAssembly production

Component assembly mechanical engineering

Device assembly

Cable assembly

Micrograph analysis

Crimping machine

Assembled cables

Cable crimping

Cable assembly Germany

Confectioned cables

Individual cable assembly

Cable assembly online

Cable assembly electrical engineering

Cable harness production

Cable harness manufacturer automotive

Electrical assemblies

Drone cable assembly

Crimping machine for cable crimping

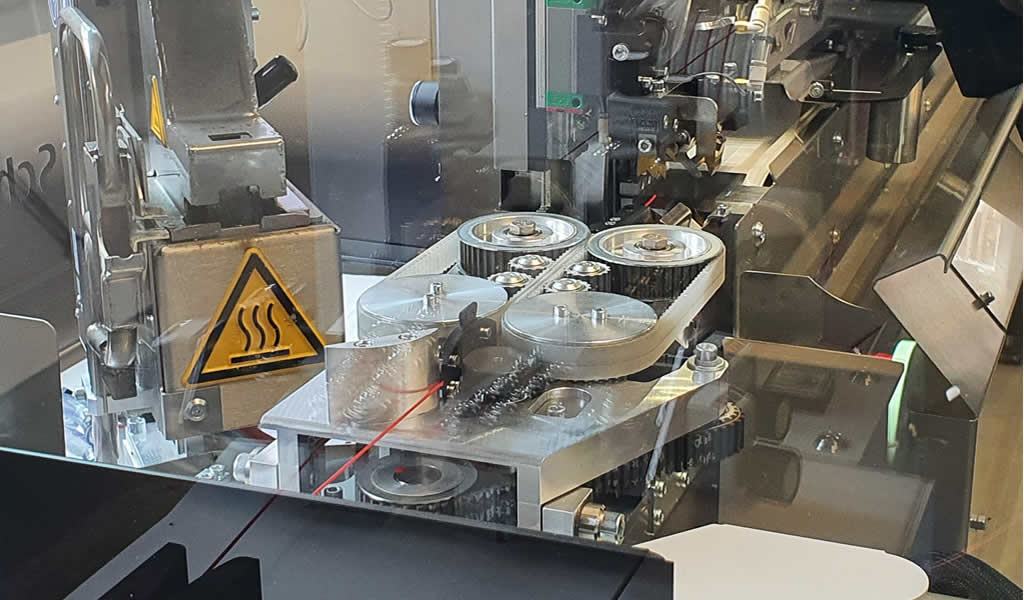

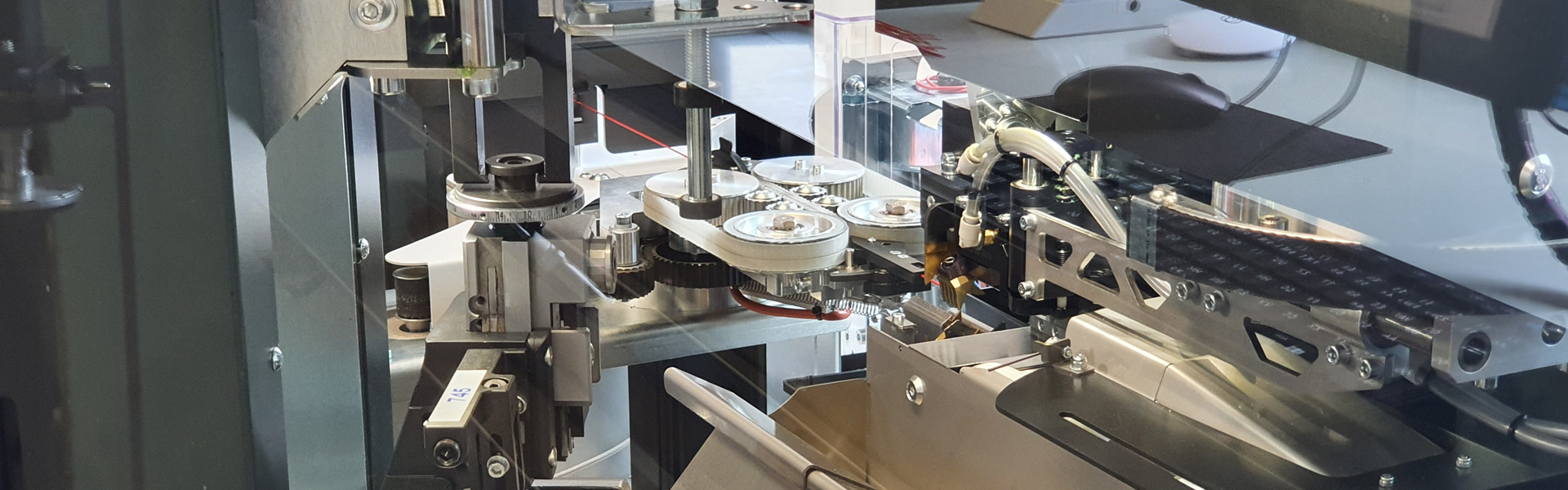

Our crimping machine crimps cables with high precision and production rates

in-Tec Bensheim is an experienced specialist in cable assembly. With the fully automatic crimping machine, we open up numerous configuration and processing options for your cables. The automatic crimping machine fulfills the various applications required, from crimping to twisting to labeling, reliably and quickly.

Cable assembly and crimping for your industry

Our customers are companies in the automotive industry, medical technology and various branches of industry. We are active as a cable assembly company on the international market. The crimping machine is located at our location in Bensheim, Germany. We support you with our know-how and are happy to advise you on your project without obligation.

Your order for our crimping machine - crimping, sealing, twisting or tin-plating

The crimping machine works with up to six processing stations and up to three crimping stations. The machine has servomotors and an intelligent control system. This consistently high machine performance enables us to reliably meet future-oriented production deadlines for you. We also take care of recurring or subsequent orders for you. In addition, it is good to know that with the automatic crimping machine we can save all production data, such as cable data, crimp data or seal data, and call them up again at any time. The crimping machine software also saves spare parts catalogs with assembly drawings or operating instructions.

Processing options of the machine - crimping cables and other applications

Crimping cables is the main task of our crimping machine. However, it fulfills many other requirements relating to wire processing. This not only includes crimping, but also twisting, tinning, labeling or stripping the cable.

Not sure whether our machine can automatically crimp your cables? If in doubt, we recommend that you have the cable or cables sampled by us. Our experts will help you quickly and easily.

Not sure whether our machine can automatically crimp your cables? If in doubt, we recommend that you have the cable or cables sampled by us. Our experts will help you quickly and easily.

- Crimp / Seal (various contacts)

- Crimp / Crimp (various contacts)

- Crimp / Crimp (same contacts)

- Crimp to crimp

- Crimp to Crimp (closed crimp zones)

- Crimping and twisting / tinning

- Hard shell seals / mini seals

- Printing and marking

- Seal / Seal (same contacts and seals)

- Seal to crimp

- Seal to Seal

- Seal and twist / tinning

- Twisting / tinning on both sides

- Twisting and tinning / crimping

- Strip in two layers

Your advantages when crimping cables

Use our machine to crimp and twist your cables. The automatic support guarantees you consistently high quality results according to your specifications. And we can also fulfill large quantities in the shortest possible time. The manual labor or even the investment in a crimping machine is no longer necessary for your company. You save costs, resources and time. You can use our competencies not only for cable assembly, but also for component assembly.

Technical data of the crimping machine

If you would like to make use of our service, we recommend that you first take a quick look at the following machine data.

If you cannot find the required specifications, we are still happy to support you. Just talk to us!

If you cannot find the required specifications, we are still happy to support you. Just talk to us!

-

Processing station: 6 (max. 3 crimping stations)

-

Raw material length: 55 mm - 65 m, optional from 35 mm

- Stripping length: Side 1: 0,1 - 18 mm, Side 2: 0,1 - 18 mm

- Outside diameter of the pipe: 4.7 mm max

- Conductor cross-section: 0,13 - 6 mm² *

- Feed rate: 8 m/s max

-

CE conformity: The CrimpCenter complies with the CE and EMC machine guidelines (mechanical and electrical safety, electromagnetic compatibility).

* Cables with hard insulation or with a tight fit of the insulation on the stranded wire cannot be processed even if they are within the scope of application mentioned above. Sampling is required for cross-sections smaller than 0.22 mm² (24 AWG) and larger than 4 mm² (12 AWG).

Cable feeder supplements the crimping machine

Crimping machines are true masters of efficiency. In order to make the production processes even leaner and more efficient, our automatic cable feeder complements the automatic crimping machine. It conveys strands and cables and feeds them gently and efficiently into the fully automatic crimping machine at a feed speed of max. 9 m / s. The feeding device removes cables from containers, barrels and conipacks. The device complies with the CE and EMC machine guidelines.

Our plus for you: Stripping machine for cables

Precise cut guaranteed! We can strip your cables. The additional machine processes coaxial, triaxial, multi-conductor and single-conductor cables. The stripping machine can also process thin, strongly adhesive and even slightly out of round insulation. The processing range is large.

- Strip the coaxial cable

- Processing of coaxial cables

- Processing of SemiFlex cables

- Processing of stranded cables

- Stripping of single conductor cables

- Full and partial deductions on both sides

- Full deductions

- Stripping of inner conductors and dismantling

- Stripping of multi-conductor cables

- Multi-layer stripping

- Multi-stage stripping

- Processing of power cables

- Processing of triaxial cables

- Twist function

- Strip in two layers