Topic areas

Contract assembly

OEM manufacturer

Assembly of components

Component assemblyAssembly production

Component assembly mechanical engineering

Device assembly

Cable assembly

Micrograph analysis

Crimping machine

Assembled cables

Cable crimping

Cable assembly Germany

Confectioned cables

Individual cable assembly

Cable assembly online

Cable assembly electrical engineering

Cable harness production

Cable harness manufacturer automotive

Electrical assemblies

Drone cable assembly

Medical Hoses

Cable crimping by specialists

When cable crimping, we create a stable cable connection. We assemble several plugs, cables, cables with plugs or complete cable harnesses for you according to your wishes. Whether single-core, multi-core cables or EMC-shielded cables - we take care of the crimping for cables.

What is crimping?

Crimping a connection through the cable is difficult to undo. This is of course also intended. In a crimping process, two components are firmly pressed together. We can crimp wire end sleeves onto cables or connect contacts from plugs to cables. We can do the crimping manually with crimping pliers and crimping devices or, especially for large series, with our powerful machines. As a specialist in cable assembly, we deliver consistently high-quality crimp connections according to your requirements.

Why is cable crimping a good way to connect?

-

Difficult to detach even under the influence of strong force.

-

Mechanical and electrical reliability.

-

Many connections can be realized in a short time.

-

If connections cannot be made using other methods, such as screwing or soldering, crimping is an option.

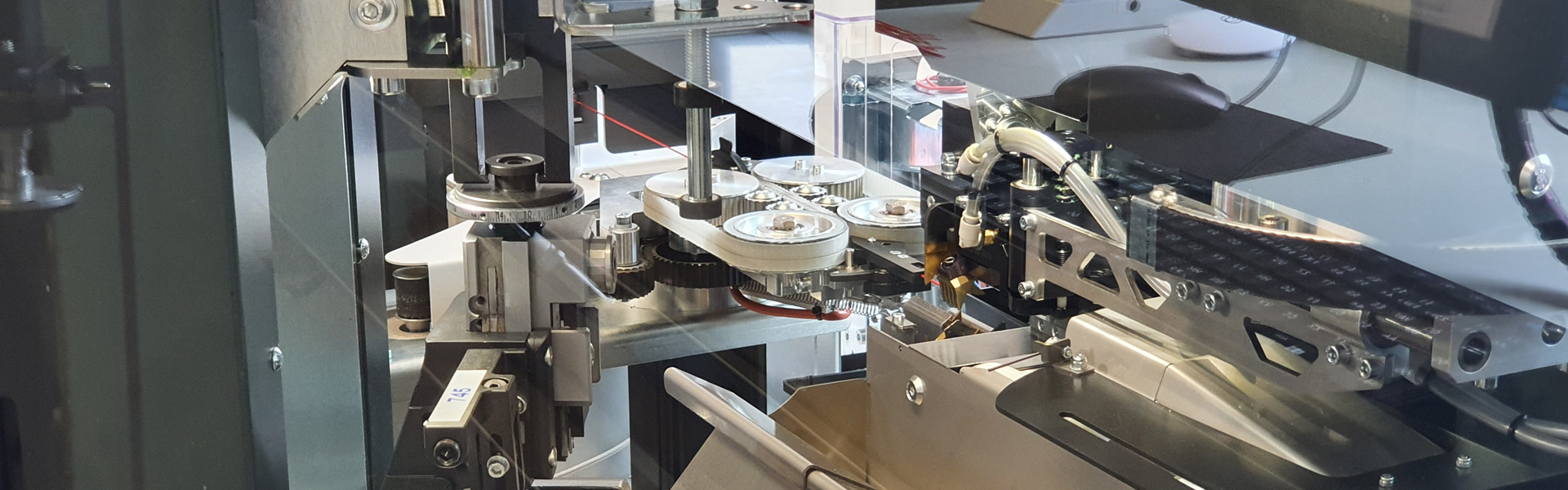

Cable crimping with machines

in-Tec Bensheim uses automatic crimping, cutting and stripping machines. Our crimping machine works with up to six processing stations and up to three crimping stations. We use this to process strands with a diameter of 0.13 to 6 mm² (26-10 AWG). The machine's software also saves spare parts catalogs with assembly drawings or operating instructions. We can easily map recurring and timely orders for cable crimping.

-

Semi-automatic crimping machines for processing punched contacts

-

Stripper crimper for turned contacts

-

Automatic cutting and stripping machines

Crimp cables - avoid mistakes

Crimping cables requires the right amount of force. The connection must not be too loose, but not too tight either, so as not to crush or destroy wires or cables. The connection must be exact so that the later connection or electrical line works. That requires feeling, experience and the right tools that we bring with us.